Manufacturing

PROGEN Production & Manufacturing

Core Manufacturing Capabilities

Pilot Scale Test Workshop

More than 30 scientific experts More than 50 self-owned core patents.

Highly efficient Production

The daily output of water light essence and freeze-dried powder reaches 200,000 bottles; The daily output of functional essence reaches 150,000 bottles.

High-Efficiency Production Line

Invested RMB 4.5 million in Sina Ailtuo’s advanced emulsification system with a production capacity of 50 tons per 8 hours.

Water Purification System

Using advanced EDI water purification system meeting medical-grade injection purification standards.

Canning System

Class 100,000 cleanroom with filling precision up to ±0.03g — 10 times higher than industry standards.

Outer Packaging Workshop

Class 100,000 cleanroom ensuring personnel-material separation, equipped with fully automatic labeling and packaging lines.

Production Equipment Highlights

FU4B series high-speed filling machines

T3925/G1M1K80 inkjet printer

XY-22 automatic round bottle labeling system

GTB-W40 vial capping machine

SD-S-0.5T medical-grade purified water system

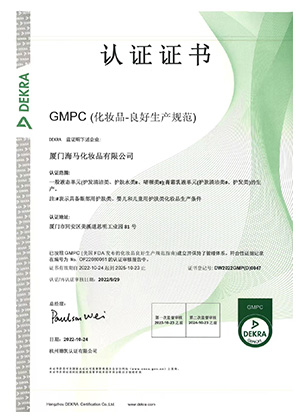

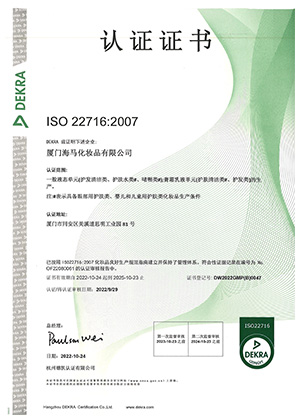

Quality & Certification

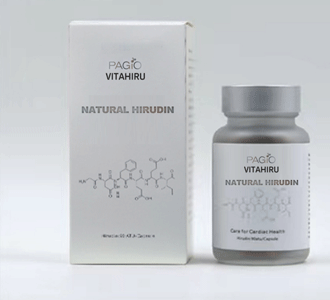

GMPC Certification

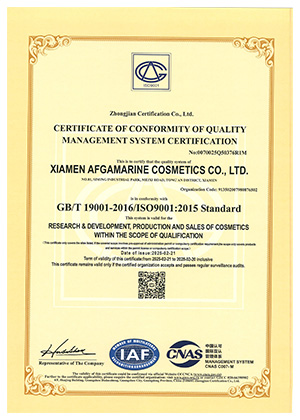

ISO 9001 Quality Management

ISO9001 Certification

Our Manufacturing Process

Our Manufacturing Philosophy

PROGEN upholds the philosophy of“Technology Empowers Manufacturing, Quality Defines Brand.”

Through continuous innovation and strict quality assurance,we deliver premium, traceable biotechnological and skincare products to global partners.)

Strict Production Process — Science Ensures Quality

Progen Biotech adheres to GMP and ISO-certified manufacturing standards,ensuring each product passes through a precise and traceable 8-step process.

Every step reflects our pursuit of scientific excellence and product consistency.

Progen 8-Step Manufacturing Process

Formulation R&D

Custom formula design, functional ingredient optimization, and stability verification.

Raw Material Inspection

Comprehensive purity, microbial, and heavy metal analysis.

Weighing & Preparation

Precision-controlled ingredient batching within ±0.03g.

Emulsification & Blending

High-speed mixing under controlled temperature and pressure.

Sterilization & Filtration

Medical-grade EDI water system with triple-stage filtration.

Filling & Sealing

Automated cleanroom filling with real-time quality monitoring.

Packaging & Labeling

Full automation for labeling, boxing, and barcode traceability.

Inspection & Shipment

COA, stability, and efficacy testing before release.

Contact Us Today to Receive Our Product Catalog and Free Sample Support.

Whether you’re seeking private label production, formula customization, or full OEM partnership,Progen Biotech delivers integrated solutions from formulation to delivery.